Cellulose Nanocrystals: Imagine Skyscrapers Able To Shrug Off The Worst Earthquakes

Early this year I wrote an article about where I saw the future heading. I suggested that one major change in our present reality would be the moving away from the use of “bulk†materials and towards materials that were cheap, plentiful, and had properties far superior to the majority of materials used for making nearly any product today.

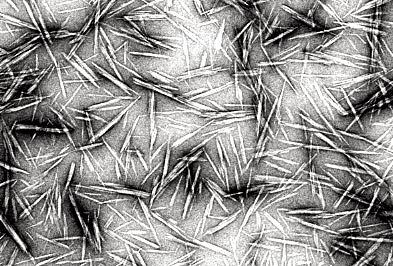

One of those materials will, in all likelihood, be Cellulose Nanocrystals, a naturally occurring substance that can be produced from nearly any source of cellulose. CNCs are a form of glucose molecule, and in their natural form provide the strength and stiffness in nearly any form of plant, from grass stalks to Redwoods. It can be pretty easily processed out of nearly any plant material, though present efforts are concentrated on wood pulp. Essentially, when you break down the cell walls of any given plant, and extract the cellulose fibers, those fibers can then be further broken down into nanofibrils, microscopic fibers about an order of magnitude smaller, which are composed of highly organized regions of CNCs and amorphous chains of cellulose which can be removed by an acid bath. The resulting material is stronger than any other manmade material but carbon nanotubes, and far cheaper to make than CNTs or Kevlar. Potentially, such CNCs could be made in such large bulk quantities that they could be competitive with other metals and plastics, and even glass.

And that’s exactly where you will see them begin to make a huge impact. Think logically about it. If you were designing a new product, and you could use a substance with a fraction the weight, many times the strength, and the same costs, which would you use? As CNC’s are essentially another form of plastic (and much less explosive than their ancestor, celluloid, one of the very first “plastics†ever discovered) with properties similar to glass (transparency) steel (strength) and plastic (can be made in any shape); it could easily be used to replace multiple materials at once in a single product. And since it’s made from bio-organic materials, it’s a renewable resource. The waste materials from agriculture, biofuels, wood manufacturing, papermaking, and nearly all other industrial processes that use plant products could be used to make CNCs.

Imagine the possibilities. A house with walls less than an inch thick that could withstand a hurricane. A car with almost no metal parts. Skyscrapers able to shrug off the worst earthquakes. While many issues still need to be worked out, such as finding ways to seal the CNCs surface to ensure it’s waterproof, there are numerous ways that this sole disadvantage can be worked around without compromising its desirable properties. From clothes to cars to skyscrapers, CNC could potentially replace thousands of different materials we use daily that are either limited in supply; expensive to refine from raw materials; or just plain hazardous to the environment. Properly exploited, it could become a “one size fits all†solution to producing nearly any physical object in a manner that is both extremely economical, biosphere friendly, and infinitely renewable.

CNCs. It’s just one of many new materials that we will see replace our current bulk materials technology, and it brings us one more step closer to a future in which everything of a material nature is so abundant that it ceases to have any real monetary value.